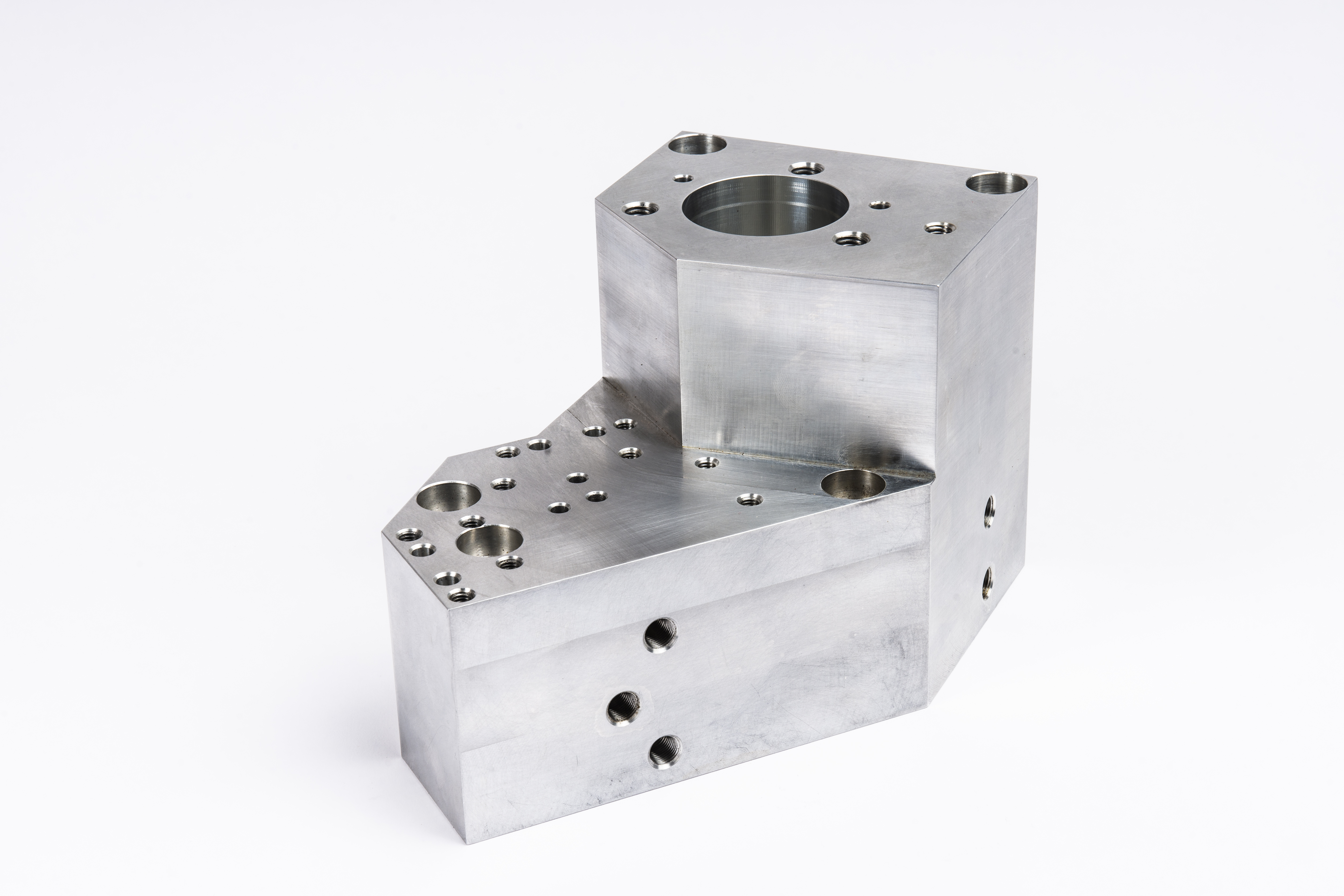

Capabilities

Optimized & Industry-ready Solutions

For all of your complex requirements and needs, turn to the experts in CNC Engineering and Machining.

Material Capabilities

Steel

Iron Based Superalloy

Alloy Steel

Carbon Steel

HSLA

Tool Steel

Ferrous Materials

Plastics

Machine / Equipment List

Machining

- HAAS VF3 3 & 4 Axis

- HAAS VF2SS 3 & 4 Axis

- Okuma Lathe

- (2) Bridgeports

Inspection Equipment

- Keyence IM 7030 Image Dimension Measurement System

- Keyence XM-T2200 Coordinate Measuring Machine

- Surface Profilometer/Laser Displacement Sensor

- Measuring Microscope

- Digital Calipers, gauges, Rockwell Hardness

- Cognex Scanners

Cutting

- 5 Do-All Saws

- 4kw Fiber Laser

Surface Grinding - All with liquid coolant

- Blanchard Grinders (38″, 42″, 60″)

- Freeport 20″ x40″

- Mattison 16″ x 72″

- 5MVMs 12″ x 180″

- OD/Slitter Grinders

Finishing

- 3 Vibratory Tumblers – Ceramic, plastic and organic media

- Wide Belt Deburring and Graining Machine 42” Wide

- Edge Rounding Machine 42” Wide

- Handheld deburring and finishing machines

Coatings and Surface Treatments

AccuCNC partners only with special processors that are ISO9001, AS9100 and NADCAP Certified.

Engraving

- 3 YAG Engraving/Marking Lasers

- 2 CO2 Engraving/Marking Lasers

- 1 UV Engraving/Marking Laser

- 2 Fiber Engraving/Marking Lasers

- 2 CO2 Large Format Engraving and Cutting Lasers 48” x 24”

- 1 CO2/Fiber Dual Source Large Format Engraving and Cutting Laser 48” x 36”

Common Surface Applications we outsource to our partner network:

- Anodize Type I, II, and III Hard Coats.

- Powder Coating

- Plating

- Passivation